Trading

We will be the leader of future value creation with accumulated technology and creativity

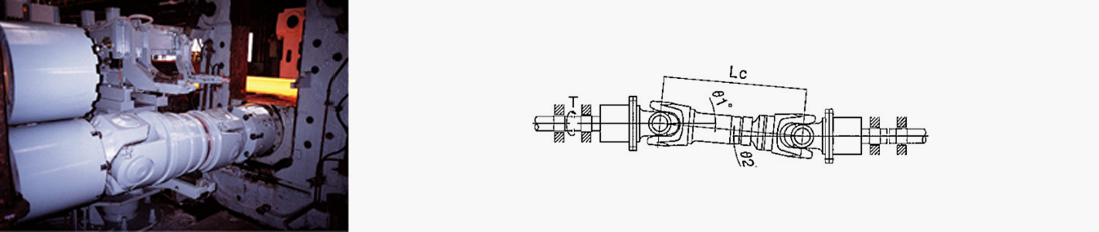

Universal Joint-NAJICO

Technology for transmitting rotation energy

It is used to transmit power by connecting shaft to shaft. In particular, power can be transmitted to rotation.

Universal joints are characterized by high performance and high reliability with high strength and accuracy, doubled by the accumulation of technology through extensive research facilities and abundant experience and performance.

It supports a variety of applications, including steel-mill facilities, railway vehicles, paper-mill machinery, and ships.

-

- S Series

- Extra large universal joint for steel mills

-

- P Series

- Medium/large universal joint for steel mills

-

- 190 Series

- General-purpose universal joint for vehicles, ships, and paper-mill.

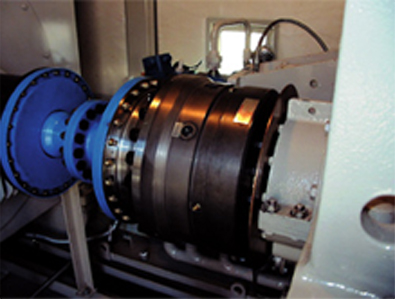

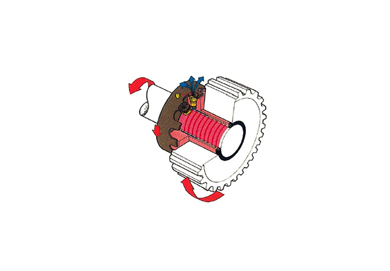

Safety Fit-NAJICO

The culmination of rotation transmission and torque control technology

This is a system that contracts the interior using hydraulic pressure and transmits torque through the friction joint.

If excessive torque is applied, the friction joint slips and the plug is cut, and at the same time, the hydraulic pressure is opened and the plug rotates.

The production line can be restarted in a short time by replacing the plug and re-pressurizing.

Polishing magnet

Grinding stones for slabs, billets, roll grinding, etc.

It is a tool for grinding metal parts and materials in single strokes.

It is used in a wide range of industries, especially the automobile, steel, and bearing industries, and boasts a top share in Japan due to its high technology.

- Delivery to : POSCO

- Manufacturer: NORITAKE, Japan

BRAR(ERICABLE)

Water coolant cable

-

-

- ROPE Lay Water cooled cables

-

- CONCENTRIC Lay Water cooled cables

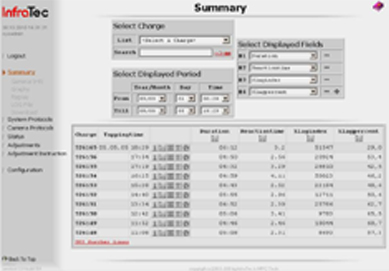

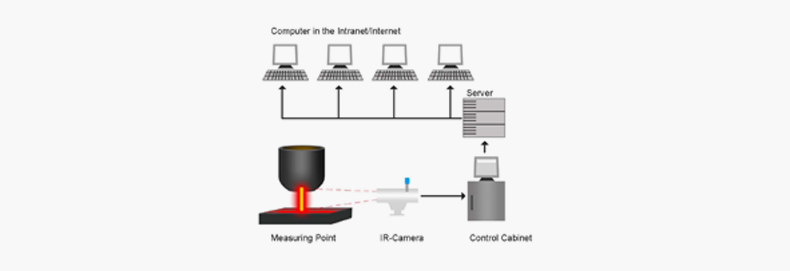

Slag Detect System

SlagDetect-Webinterface standard l Quick analysis of system data

Slag Detect camera system (German MPC TECH)

- Customer

- Hyundai Steel, POSCO and other steel facilities.

- Product features

- This is an equipment system for the production of high value-added steel by minimizing slag by detecting leakage through the radiant heat difference of molten steel, which causes slag to leak into the ladle during converter steel tapping, which reduces the quality of post-process refining work.