VACUUM FILTER

(TVF TYPE)

- Leader in the new precision filtration area

- Dirty liquid from M/C penetrates belt filter in vacuum tank for filtration. Sludge from conveyor is released outside and belt filter operates consecutively with automatic cleaning.

It does not need to replace the Belt Filter and automatic dirty liquid filtration, sludge dehydration and release are made, which is an optimized new filtration system

Feature

- Economic feasibility

- No filter pump required to save running cost

- Maximize dehydration effect that minimize dry sludge release and liquid loss

- Semi-permanent without belt filter replacement by automatic cleaning function

- mproved function and efficiency

- Various belt filter and subsidiary material used by the level of filtration which enables to prevent minute chip sedimentation and to enable customized precise filtration

- Excellent maintenance

- Easy maintenance by full automation from dirty liquid filtration, sludge dehydration and release

- Minimized space for installation

- Very compact and optimal size with maximized efficient size of belt filter

Use

- Processing

- Filtration of cutting, grinding and cleaning oil of machines

- Industrial waste water

- Waste water treatment on industrial machine, press and iron industry

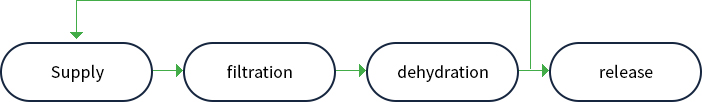

Filtration process

- 1Supply (Pumping)

- Supply clean liquid from belt filter to absorb supply pump for processing M/C

- 2Filtration (Belt Filter)

- Precision filtration available by forming sedimentary layer on the belt filter surface of dirty liquid

- 3Dehydration (Conveyor)

- Dehydration carried out by repetitive operation in a regular distance by conveyor in vacuum pressure detector and circulation cycle

- 4Release (Washing)

- Clean the belt filter surface by releasing sludge