Vacuum evaporation system

(VACUDEST)

- Leading the new wastewater treatment environment field

- H2O GmbH's vacuum evaporation system is a technology that treats wastewater by boiling it in a vacuum, and is a system that separates and discharges concentrated wastewater and distilled water. Distilled water can be treated separately according to the water pollution level and then discharged, or it can be used as industrial water that is recycled within the factory.

Features

- High economic efficiency

- Heater-free system maximizes energy efficiency by 95%

- Applicable to zero discharge system and public wastewater treatment facility discharge

- Improvement of function and efficiency

- Tanhay’s filtering KNOW-HOW and products from German H2O GmbH provide the best system, consulting, and after-sales service.

- Separation of oils and heavy metals with very high reliability during the production of distilled water

- Excellent maintenance

- Auto-cleaning function simplifies maintenance and reduces labor costs.

- Blocks odor generated by sealed structure at the source.

Purpose

- Industrial wastewater

- Wastewater treatment from machine tools, rolling, steel, etc.

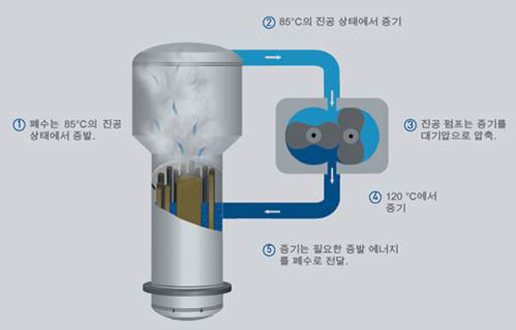

Working principle

VACUDEST's technology is based on the simple principle of separating substances based on differences in boiling points. Industrial wastewater evaporates in a vacuum, lowers its boiling point at low pressure, and is heated by compression through a compressor. The hot steam is reused to evaporate the wastewater. The clear distilled water produced can be reused as industrial water and discharged to public sewage and wastewater treatment facilities.

Tanhay Co. is the exclusive Korean distributor of H2OGmbH, a German wastewater company.