PRECOAT FILTER

(TPF TYPE)

- Excellent choice for high precision processing

and food filtration - By adding diatomite on the filter tube surface to form a pre-coat,

it executes high precision filtration through minute vesicular of

diatomite layer.

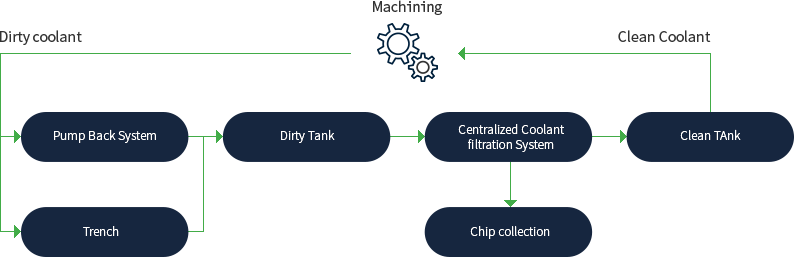

System principle

- This system is to collect water soluble and non-soluble coolant with anticorrosive, coolant and lubrication elements for cutting, grinding and rolling of mechanical works to separate chip and to filter coolant. It is resupplied to M/C with accurate amount, pressure and temperature so that it reduces running cost and to prevents environmental pollution through resource recycling.

Feature

- Applicable to various liquids

- Optimal for high precision filtration for soluble and non-soluble with its low pressure and even coating using diatomite

- Low operation cost

- Economic as small filtration material replaces elements without filter element change

- Excellent maintenance

- Easy maintenance by full automation from dirty liquid filtration, sludge dehydration and release

- Excellent dehydration

- Forming cake by dehydration of sludge to the receiver tank

Use

- Food, drink

- High precision filtration of food and drink and cooking oil

- Processing

- High precision filtration of cutting, grinding and cleaning oil of machines

- Chemical

- Chemical area including caustic soda and medical manufacturing process

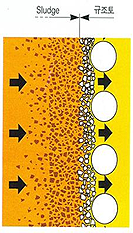

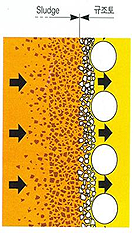

Filtration process

- 1Pre-Coating

- Form cake on the filter tube surface by serial circulation of diatomite and liquid

- 2Filtering

- Remove pollution particle by penetrating dirty tank liquid through filter tube

- 3Bumping

- Keep clean filter tube surface by removing sludge and diatomite with vertical vibration of tube

- 4Sludge transfer

- Move sludge to receiver to take deoiling by repetitive operations